BRIDGE CONSTRUCTION

Pre-type protection tube for prestressing

Pre-type protection tube for prestressing

Diorit post-tensioning systems offer innovative products and systems for the construction industry with production in their own hall in Odžak, Bosnia and Herzegovina.

In order to avoid the complicated requirements for the installation of prestressing cables on construction sites, the DIORIT company started production and offered to the market a pre-assembled system of “pick and place” prestressing cables that can be used flexibly, thus saving time and labor of the contractor. This very step meant that we were the “first” in the production of prefabricated prestressing pipes in the Balkan region.

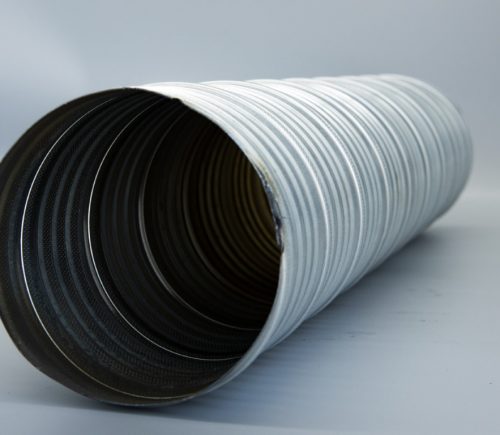

Diorit d.o.o. manufactures these protective tubes for post-tensioning in black and galvanized material. The use of these pipes in modern construction is widely accepted, and they are especially used for pre- stressing or post-stressing of concrete structures as a building material, in the construction of bridges, construction of railways and highways, underground facilities, buildings and canals.

Pipes made of steel tapes for prestressing cables and connectors for said pipes are used as protection and guide of cables-ropes for prestressing in the subsequent prestressing of concrete structures.

Declaration data – product performance

- subject to the declaration of conformity – steel strip pipes for prestressing cables and couplings for said pipes EN 523 and EN 524

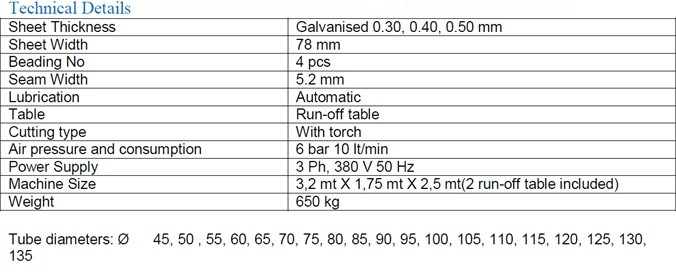

- material used – pipes made of steel strips with a thickness of 0.3 – 0.6 mm and a width of 78 mm, quality according to standards EN 10139/10140 and EN 10346

Test results:

The quality and characteristics of steel strip pipe products are in accordance with the regulations of the EN 524 1-6 standard. The measured thickness of the pipe during production was 0.3 mm to 0.4 mm, which corresponds to category 1. A thickness of 0.5 mm to 0.6 mm corresponds to category 2 of the above-mentioned standards.

Our production in one shift amounts to 4500 m’.

Available pipe diameter: from fi 45 mm to fi 135 mm.

BS

BS