GEOTECHNICAL CIVIL ENGINEERING, TUNNELING AND MINING

SN anchors

SN – Passive rod anchor from ribbed reinforcing bar

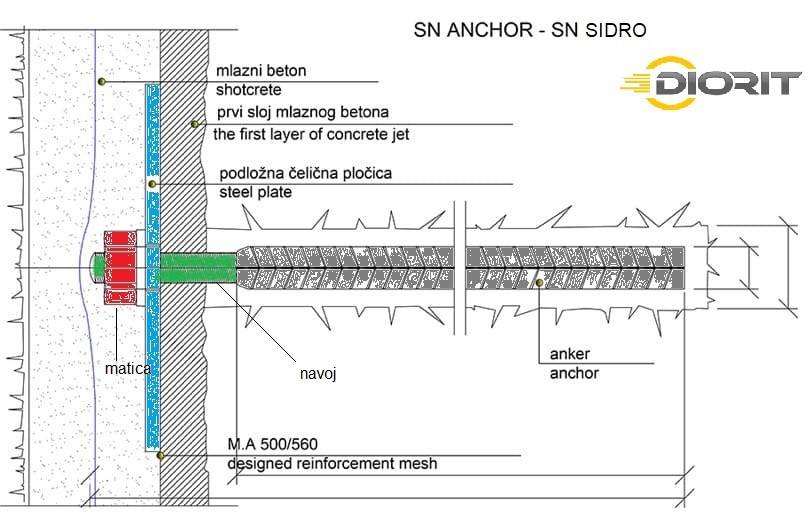

Diorit’s SN-bar anchor uses a reinforcing bar as a load-bearing element, which has a metric thread on one side.

SN rod anchors are used in more demanding, steeper terrains, and in the construction of tunnels. It can be installed on earthy and rocky terrain (tunnels, slope stabilization, various fixings).

Rock and soil anchoring is a construction technique used to increase and maintain the stability of a rock or soil mass. The installation of anchors as reinforcing elements increases the shear strength of the terrain. In this process, anchors are mainly subjected to tensile load.

The SN anchor consists of the following elements:

- Anchor rod – Reinforcing ribbed rod, different nominal diameter (eg 25, 28, 32 mm);

- Nuts – machined from hexagonal steel;

- Base plates – produced on a press from flat steel;

- Distancer (centralizer) – finished goods.

The field of application of the rock and soil anchor system includes the following areas:

- Slope protection,

- Embankment protection,

- Protection of construction pits,

- Slope protection combined with nets

- Securing the tunnel and creating an open tunnel front.

The rock and soil anchor system can be used in compact and loose soils and rocks.

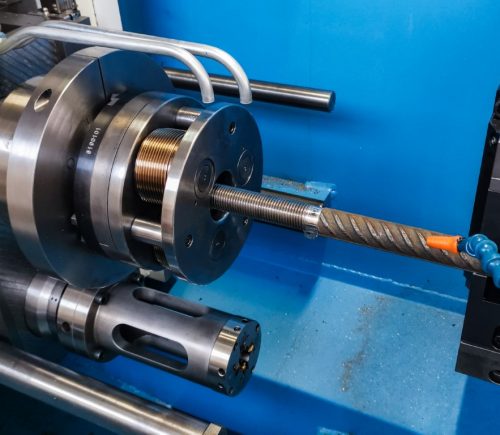

The anchor rod is obtained when a suitable thread is cold-rolled on the reinforcing rod on one side of the ribbed reinforcing rod. The base plates are made from steel flat sheets (flat steel/flach). The hexagon nut is non-standard, with a standard metric thread, it is purpose-built in a CNC machine from hexagonal material.

When installing the anchor rod, a plastic spacer is used to properly center the anchor in the hole. The spacer is made of PVC material. Since the spacer is a lost commodity and remains whole in the concrete, only the dimensions are controlled. During the installation process, the embedded anchor has a protective layer of injection compound.

The SN anchors we produce are temporary solutions and solutions with an extended life span.

Depending on the required lifespan, the installation is carried out according to the instructions:

- Anchors for temporary use, lifetime up to 2 years – no anti- corrosion protection required;

- Anchors for extended use, service life up to 15 years – protection of the entire anchor with concrete is required.

Permanent SN anchors

The function of the anchor is for the durability and safety of the building. In order to perform its function, anchors must be protected. The most important protection of an anchor is protection against corrosion. Corrosion is an electrochemical process that takes place on the surface of any metal, if the metal comes into contact with oxygen and water. Before any corrosion protection, the bars or ropes must be completely clean.

The head of the anchor is the most sensitive part because it is exposed to the elements and is the most difficult to protect.

External parts are galvanized (HGD hot dip galvanized) in the factory or production facility. Galvanization consists in the electrolytic process of coating steel with a layer of zinc. Good adhesion is achieved with the injection mixture, it is resistant to abrasion during transport and does not need further protection. Another possibility is covering with epoxy preparations. In its production, with the help of its partners, Diorit is also able to offer permanent SN rod anchors, the use of which can be up to 100 years.

Performance of work, keeping a diary and carrying out tests are mandatory according to the appropriate norms for the performance of work and tests. SN anchors can be stored outdoors in a covered area, or outdoors and protected from weather conditions.

Diorit d.o.o. for its production of SN anchors, it has the most important certificates (FACTORY PRODUCTION CONTROL CONFORMITY CERTIFICATE) and is accredited for the EU and the world through ZAG, the leading institute in the field of construction in Slovenia.

In this regard, the INSTITUTE FOR CONSTRUCTION OF SLOVENIA (ZAG) continuously supervises our production. The scientific research activity of ZAG is undoubtedly one of the most important institutes in the EU in terms of content and strategy.

BS

BS