GEOTECHNICAL CIVIL ENGINEERING, TUNNELING AND MINING

IBO-SDA-SBS self-drilling anchors

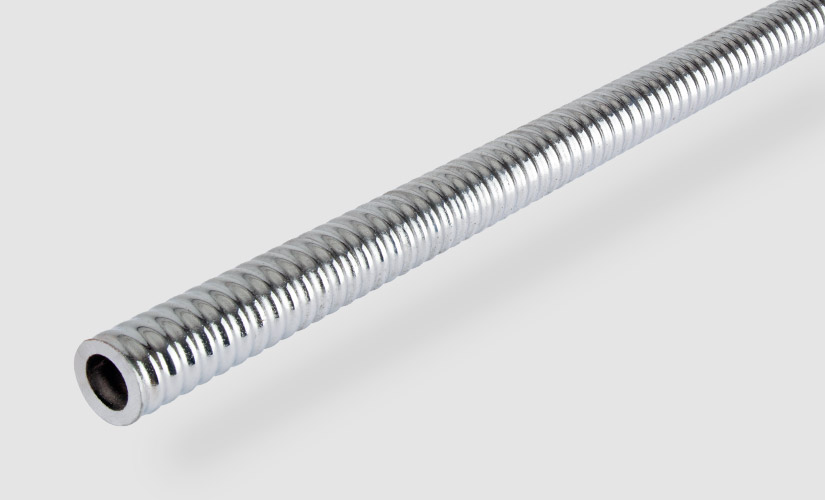

Diorit IBO-SDA-SBS self-drilling anchors from hollow steel tubes

Anchoring systems are used in various ways in mining and tunnel construction and are used for temporary rehabilitation and protection of the sides or ceiling of the tunnel during its construction. Geotechnical anchors represent a special element in the group of geotechnical constructions that strengthen the natural terrain behind the soil profile or protective structure in a special way. Anchors transfer the tensile force from the structure to the ground. The shear strength of the surrounding soil is used to transmit the tensile force.

Diorit d.o.o. has its own production of IBO-SDA anchors in the production facility in Odžak in Bosnia and Herzegovina. Self-drilling IBO-SDA (Self-drilling anchor) anchors are a special type of rod anchors.

Each anchor consists of the following elements:

- hollow steel pipes of appropriate outer and inner diameter (R32, R38, R51)

- supporting plates of suitable dimensions, – nuts: domed and hex (R32, R38, R51)

- connectors (R32, R38, R51)

- spacer-centralizer (R32, R38, R51)

- suitable disposable drill crowns (R32, R38, R51)

The IBO-SDA anchor rod is obtained when a round thread is machined on a steel pipe. This is done in a thread rolling machine. The shape of the thread is determined according to a strictly defined norm. Anchor elements are produced in sections of standard length (2, 3 or 4 m) and, if necessary, continue with appropriate connectors.

The base plates are made from steel flat sheets (flat steel/flach). The geometry of the base plates and the types of plates depend on the customer’s requirements, and Diorit certainly offers a wide range of the aforementioned base plates in its production.

Couplings are non-standard goods, with a standardized round thread, they are specially produced by various machining procedures.

Types of connectors: R32, R38 and R51.

When installing the anchor rod, a plastic spacer is used to properly center the anchor in the hole. The spacer is made of PVC material. The spacer is considered as lost goods and remains intact in the concrete.

Planning, dimensioning, execution, testing and quality control for IBO- SDA anchors can only be carried out by companies with appropriate expertise, experience and technical personnel with appropriate training. Responsibilities for planning, dimensioning, execution, testing and quality control must be defined in the contract for the execution of the project. The manufacturer of the anchor components must ensure their compliance with the permit. The responsibility for the same lies with the permit holder.

Diorit’s IBO-SDA rod anchor uses a hollow rod with a continuous round thread as a passive load-bearing element. A steel tendon is a hollow steel rod with cold-rolled threads and therefore can be cut or joined at any desired point. IBO-SDA anchors are installed in rock or soil by drilling and grouting using a drill and a lost-disposable crown. During drilling, the hollow rod is also used for flushing the hole with water, air or cement mixture. Injecting the hole with cement mortar is done through the pipe and the crown and can be done after drilling the entire hole, or it can also be done simultaneously with drilling. By drilling the anchor of the appropriate length, the installation of the anchor was completed. The injection of the anchor is performed through the anchor itself, with the injection mixture coming out through the holes on the drilling head, until the injection mixture starts to come out at the mouth of the well.

IBO-SDA rod anchors are used in more demanding, steeper terrains and in the construction of tunnels. It can be installed on earthy and rocky terrain (tunnels, slope stabilization, various fixings). Rock and soil anchoring is a construction technique used to increase and maintain the stability of a rock or soil mass. The installation of anchors as reinforcing elements increases the shear strength of the terrain. In this process, anchors are mainly subjected to tensile load.

The field of application of the rock and soil anchor system includes the following areas:

- Slope protection,

- Embankment protection,

- Protection of construction pits,

- Slope protection combined with nets

- Securing the tunnel and creating an open tunnel front.

The IBO-SDA rock and soil anchor system can be used in compact and loose soils and rocks. The advantages of self-drilling anchors are in the possible significant length of the execution, as well as avoiding the possibility of the well collapsing due to the extraction of the drill rod and the investment of the anchors in the classic procedures of the execution of the anchors, and the use in damaged rock masses.

Characteristics of the IBO-SDA rod anchor:

- Nationally approved system with internal and external quality control;

- Well adapted to transport and assembly conditions, delivered in parts with connectors;

- A wide selection of drill bits allows for use in different types of soil;

- It is easily adapted to the required length on the construction site, with different geological conditions using smaller parts with connectors;

- Excellent connection between anchor and cement mortar thanks to threaded ribs;

- It can be precisely adjusted to the required loads thanks to the wide radius range;

- High speed of construction, since drilling, installation and grouting are done in just one operation.

Available types

- Temporary anchors:

– Temporary anchors (useful life up to 2 years) - Semi-permanent anchors:

– Semi-permanent anchors, untreated, the rate of corrosion depends on the composition of the soil (service life up to 50 years)

– Semi-permanent anchors, hot-dip galvanized, the rate of corrosion depends on the composition of the soil (service life up to 50 years)

Permanent IBO-SDA anchors

The function of the anchor is the durability and safety of the building. In order to perform its function, anchors must be protected. The most important protection of an anchor is protection against corrosion. Corrosion is an electrochemical process that takes place on the surface of any metal, if the metal comes into contact with oxygen and water. Before any corrosion protection, the bars or ropes must be completely clean.

The head of the anchor is the most sensitive part because it is exposed to the elements and is the most difficult to protect.

External parts are galvanized (HGD hot dip galvanized) in the factory or production facility. Galvanization consists in the electrolytic process of coating steel with a layer of zinc. Good adhesion is achieved with the injection mixture; it is resistant to abrasion during transport and does not need further protection. Another possibility is covering with epoxy preparations. In its production, with the help of its partners, Diorit is also able to offer permanent IBO-SDA rod anchors whose time use can be as long as the expected life of the project.

IBO-SDA anchor with elements: anchor rod-anchor body, support plate, nut and coupling

Thread rolling process for IBO-SDA anchors in the modernly equipped production plant of the Diorit company in Odžak-BiH

Example of installation of IBO-SDA self-drilling anchors in a tunnel

Packing of manufactured IBO-SDA anchors with a pneumatic tie

BS

BS